Selecting the Appropriate Resin

Selecting the Appropriate Resin

For a 3D printer to be useful to your orthodontic practice, it needs to be capable of producing dental models, appliances, and other essential objects. Thus, you’ll need the right resin materials on hand for your fancy new printer to do it’s job effectively.

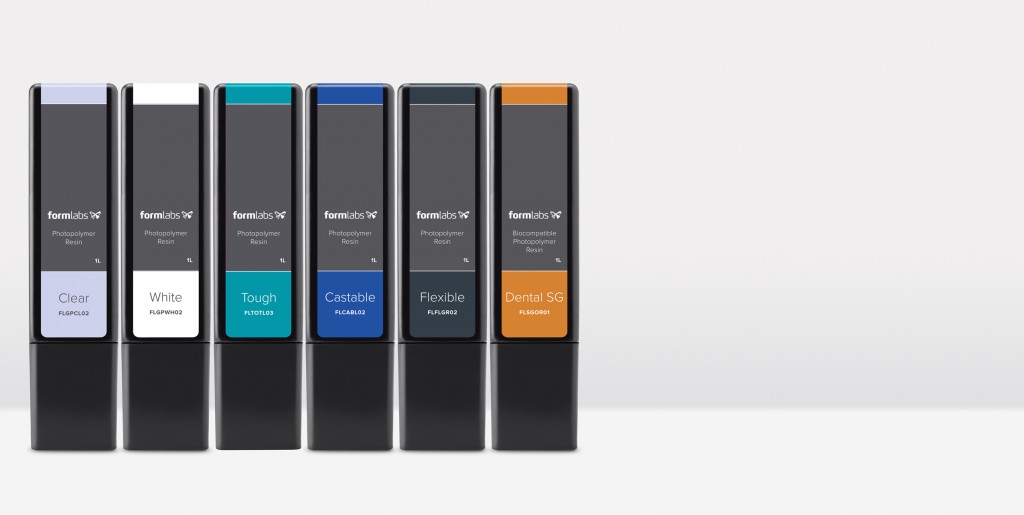

The important thing to understand is that resins are custom formulated and printer specific, so you can’t exactly use a generic resin and resins typically cannot be used between different brands of printers, though there are occasional exceptions. Manufacturers will also have a number of different resin options for orthodontists to select from, and you’ll have to choose different resins based on the desired print resolution, print color, and whether or not the resin material should be bio-compatible. Selecting the appropriate resin for the job comes down to how the prints will end up being used.

Resins for Orthodontic Models

When it comes to selecting a print resolution for orthodontic models, and in turn the appropriate resin for that resolution, 100microns is more than enough detail to produce high quality models for diagnostic purposes, retainers, or other appliances. You can always choose to print at a higher resolutions if you desire, it will just take a lot more time to print. When submitting printed models for board ABO board certification, it is recommended by the ABO that you submit the highest quality prints (<30micron resolution) for grading.

Naturally, printed orthodontic models turn out best when they are printed using an opaque material, so it is easy to see fine details across the models. Most 3D printer manufacturers in the dental space seem to think that we like colors that resemble yellow dental stone, so with many companies you’ll get some form of beige or yellow-stone type resin as an option. With my Juell Flash OC printer we use the taupe colored resin, and both Sean and I prefer the standard grey resin for our Form 2 printers.

Colored resins get their color from pigment particles which have different chemistry than resin, so they won’t dissolve in the material, unlike other components. Particles with similar chemistries like to group up, so one of the potential challenges with using pigmented resins is keeping these particles from clumping together and settling. Depending on the resin formulation and type of printer, some manufacturers are able to insert additives to the resins that will help keep the colored particles separated. Other resins may require you to shake the container before adding resin to the vat, or to stir the vat to prevent settling if the printer has been inactive for some time.

Colored resins get their color from pigment particles which have different chemistry than resin, so they won’t dissolve in the material, unlike other components. Particles with similar chemistries like to group up, so one of the potential challenges with using pigmented resins is keeping these particles from clumping together and settling. Depending on the resin formulation and type of printer, some manufacturers are able to insert additives to the resins that will help keep the colored particles separated. Other resins may require you to shake the container before adding resin to the vat, or to stir the vat to prevent settling if the printer has been inactive for some time.

Resins for Indirect Bonding Trays & Occlusal Splints

With the appropriate lab software, 3D printers also allow for orthodontic appliances to be printed directly without having to use a physical model. The same minimum resolution requirement of 100 microns applies with direct printed appliances, though many bio-compatible resins are only designed for printing at higher resolutions.

It should be fairly obvious that when printing indirect bonding trays & occlusal splints, we’d want to select a clear resin material, but since you are also printing medical devices in this case, be sure to use a resin that is bio-compatible. Some companies offer a somewhat flexible resin to print indirect bonding trays, but this less accurate and can make full seating of the tray less predictable, especially if a team member mishandles the softer tray. In the case of both occlusal splints and indirect bonding trays, you will be better served by printing in a clear, rigid material as in the image below.

Switching Between Resins

Since different resins will be required for different orthodontic indications, another important consideration in purchasing a 3D printer and designing your workflows is how easily you are able to changeover between materials. Some companies like FormLabs, with their cartridge based system and stackable resin tanks, make this process extremely easy, but you may find this difficult with other printers. Top-Down style 3D printers like the Juell Flash OC from Park Dental Research make it especially difficult to change resins, so they are best designed for high capacity printing of a singular material.

Leave a Reply