To base or not to base, that is the question: Whether tis nobler in the mind to suffer additional 3D printer workflow. That is a question that is common these days as 3D printing grows in orthodontic practices. On the one hand models with bases look so nice, and seem to fit our traditional expectations of a study model. On the other hand, how much resin and time do you need to put into these add-ons, and are they even necessary?

Whether you do this workflow step or not, depends on the purpose of your 3d print. I will be reviewing some of the reasoning behind adding bases to dental arches, and how that decision impacts your 3D prints, especially if you are using the Form2 printer.

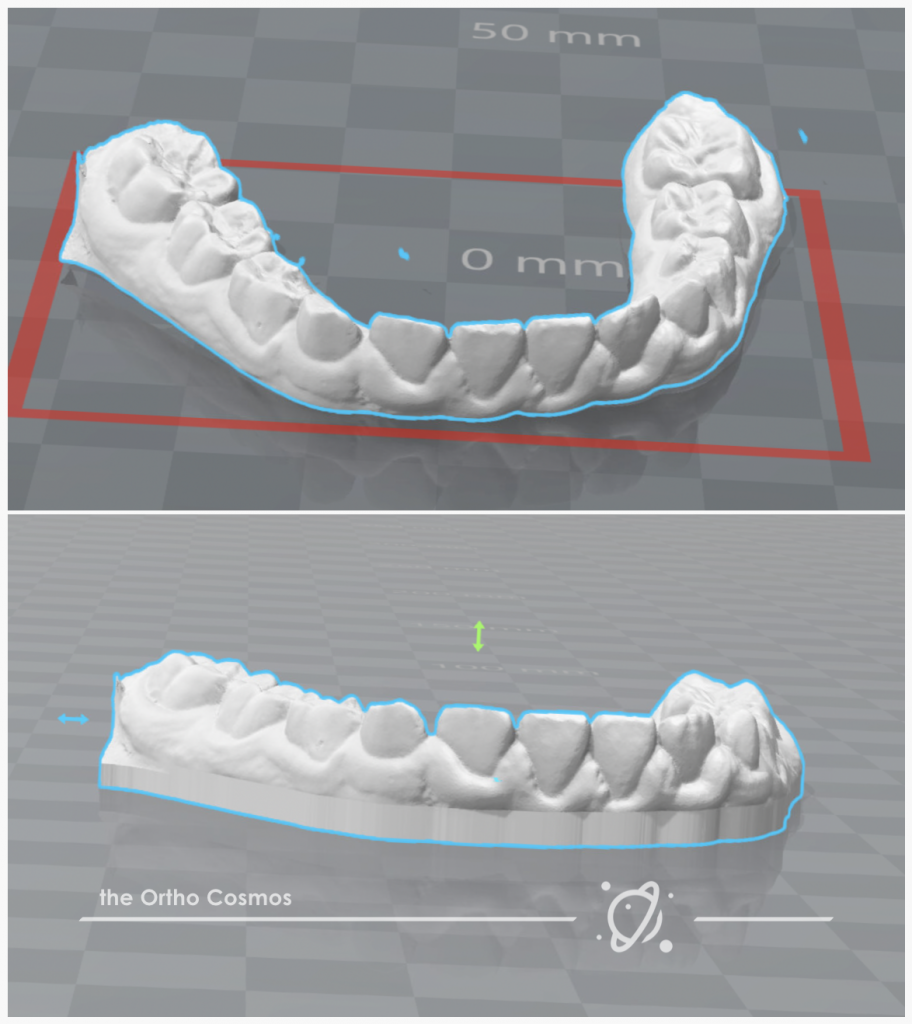

If the model’s intended use is for presentation, then a nice base is recommended to prepare the model for display. A base makes the model more presentable and gives a flat surface where supports could be avoided in the print process. The flat base and the print could be further improved by hollowing the model. As long as the wall thickness maintains a good dimension, the print will have reduced amount of resin. The software that hollows a base, though, is not readily available. To add bases to models, software such as meshmixer, 3D builder or OrthoAnalyzer can be integrated into your workflow.

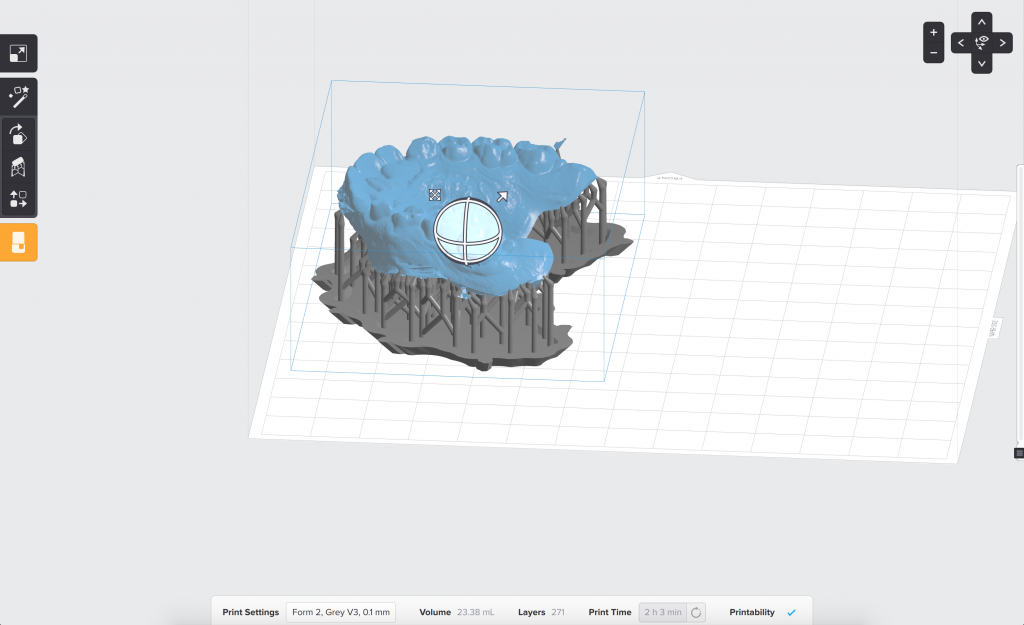

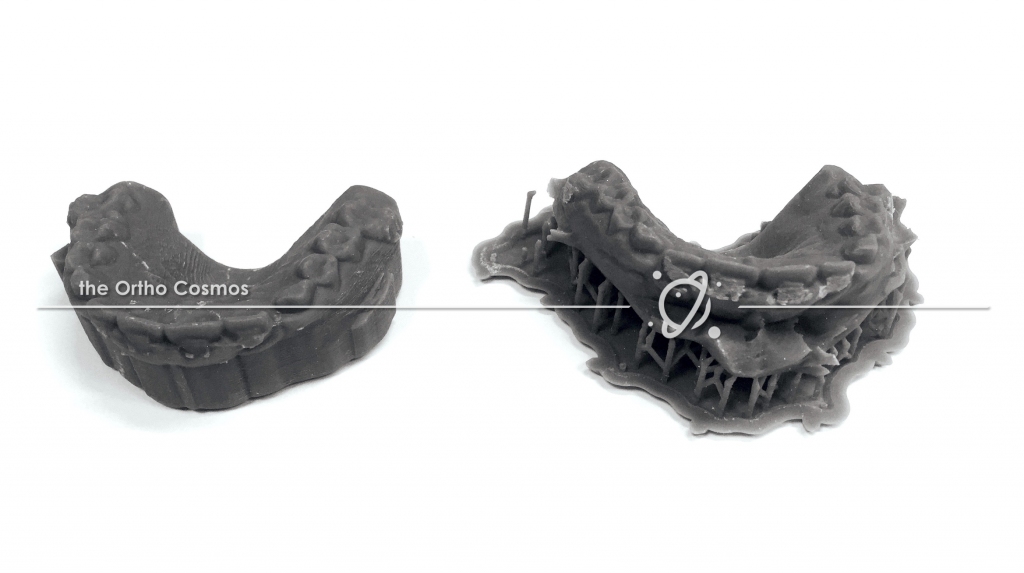

Save the time in preparing the print by taking the clean stl into your preform software and add supports. The supports will give a stable, mesh base to the print that allows the lab access to the model to make appliances, while decreasing the amount of resin. In the example print (Fig 1) the upper arch impression will be used to fabricate a hawley retainer for a patient completing Phase I treatment. Without a base, the model’s volume is 23.4 mL and would take 2 hours and 3 min to print.

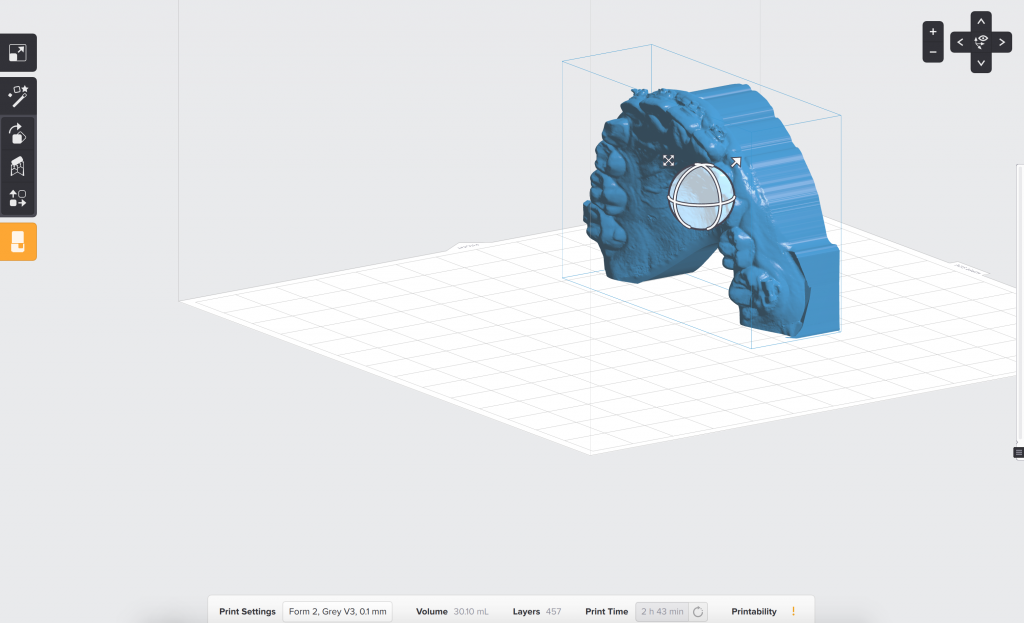

Contrast that to the same model with a flat base where the volume increased to 30.1 mL and would take 2 hours and 43 min to print (Fig 2). Not to mention the laboratory staff time it took for the base to be added to the model.

Dental arch scans are often a raw image captured with limited extensions into the vestibule and lack the traditional rolling that we see in other impressions. When there is limited data of the tissues around the teeth, the 3D print may need greater thickness so it is not damaged in the printing process or when making the desired appliance. In these circumstances, it is important to reinforce the print. When vacuum-forming an appliance, an uneven base with a thin profile will likely crack the print due to the lack of structural support. Adding a base to these prints will gain the strength necessary.

Adding bases to prints can seem like a tedious process, but setting preferences in your digital lab will help drive the proper workflow.

Leave a Reply