When purchasing a 3D printer for your orthodontic practice, it is important to understand how the various styles of 3D printers differ from one another and how this can impact print speed and quality.

There are 3 basic styles of 3D printing:

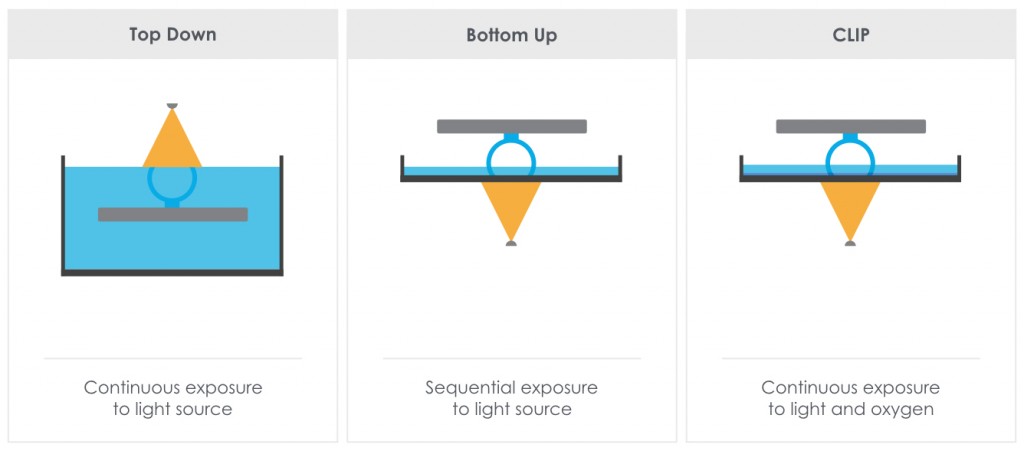

- Bottom Up Printing, where resin is cured through a window in the bottom of the vat by a light source from below. In this style of printing, the build platform is raised out of the resin vat and a ‘peel’ step is required between each layer in order to detach the cured material from the bottom of the vat. This ‘peel’ step is by far the slowest part of SLA printing with most modern light sources.

Printer Examples: Formlabs Form2, Envisiontec Vida, Structo Orthoform, etc. - Top Down Printing, where resin is cured by a light source above the vat and the build platform is lowered down into the resin vat. Rather than a series of alternating light exposures and ‘peel’ steps this style of printing uses continuous light exposure (like a movie) to cure the resin and can achieve exceptionally high print speeds due to the lack of a ‘peel’ step.

Printer Examples: Juell Flash OC - Continuous Liquid Interface Production (CLIP), where resin is cured through an oxygen permeable window in the bottom of the vat by a light source from below. The oxygen layer over the window keeps the resin from sticking to the vat and continuous light exposure can be utilized because no ‘peel’ step is required. CLIP essentially is a bottom up printing technique without the ‘peel’ step, so top down style print speeds can be achieved. CLIP technology is currently very cost-prohibitive.

Printer Examples: Carbon M1

Most consumer SLA printers, and those in use in orthodontics, will utilize bottom-up-and-peel techniques for several reasons:

- Less resin is required to fill the vat if a part is being pulled out of the resin versus being lowered into the resin so less resin has to be purchased at once.

- Since a smaller resin vat is needed, bottom up printers can be built smaller and they tend to have fewer mechanical parts, such as leveling devices submerged in resin.

- Manufacturers see the resin vats and windows used for bottom up printers as a profit-generating consumable since they will have to be replaced somewhat frequently due to wear and tear.

Register as a free Ortho Cosmos member to gain access to exclusive materials on digital orthodontics and other cutting edge topics.

Leave a Reply