Orthodontic treatment continues to evolve. Our digital future means additional diagnostic tools and treatment modalities that augment and expand the application of our specialty. The application of 3D printing into orthodontics was introduced by the Invisalign product. By using 3D printing technology which was developed by Charles Hull in 1983, and sold by 3D Systems, Align Technology added a niche into the orthodontic market.

Orthodontic treatment continues to evolve. Our digital future means additional diagnostic tools and treatment modalities that augment and expand the application of our specialty. The application of 3D printing into orthodontics was introduced by the Invisalign product. By using 3D printing technology which was developed by Charles Hull in 1983, and sold by 3D Systems, Align Technology added a niche into the orthodontic market.

The current technology in 3D printing has been evolving in manufacturing functional parts and expanding the applicability of this process. As patents have expired in the 3D printing processes, we are seeing the commoditization of 3D printing. This is one of the reasons why this process has become so popular. The next evolution in the process has been in the expanded consumer access to lower cost solutions to enter the space. What was once only available to large manufacturing corporations and commercial laboratories, can now be owned and operated by orthodontic practices, schools and even the average consumer.

The challenge with 3D printing, is that it is a static process. In the dental industry, this digital process facilitates static restorations and provides an opportunity to improve the efficiency of laboratory workflows. When it comes to orthodontic treatment, our treatment is dynamic. 3D printing serves an immediate benefit for growing study models for traditional lab fabrication. This benefits offices in removing the alginate or PVS impressions, but leaves the untapped potential of the digital tools. When making a series of aligners, movement can be staged and adjusted in sequence to turn a static model into a series of models with a progression of movements. In order to change a static process into a dynamic appliance, the future for orthodontics is in 4D printing.

4D printing is a digital process that takes 3D printing materials and adds the 4th dimension of time. This is accomplished by adding movement into the 3D printed parts and manufacturing appliances that change in shape over time. The stimulus for such movement is a change in temperature, a charge or kinetic process that alters the shape of the 3D printed object. Think of it as adding a Niti wire to move a tooth vs. a series of wires with progressive bends to achieve the desired tooth position. When you think of it in that dynamic, you can realize that in the same way Nitinol wires revolutionized bracket systems, 4D printing can revolutionize the future of digital orthodontic treatment. Whether they are fixed or removable, 4D printed appliances would improve the efficiency of treatment and utilize digital workflows to incorporate many of the imaging and diagnostic tools we have available today.

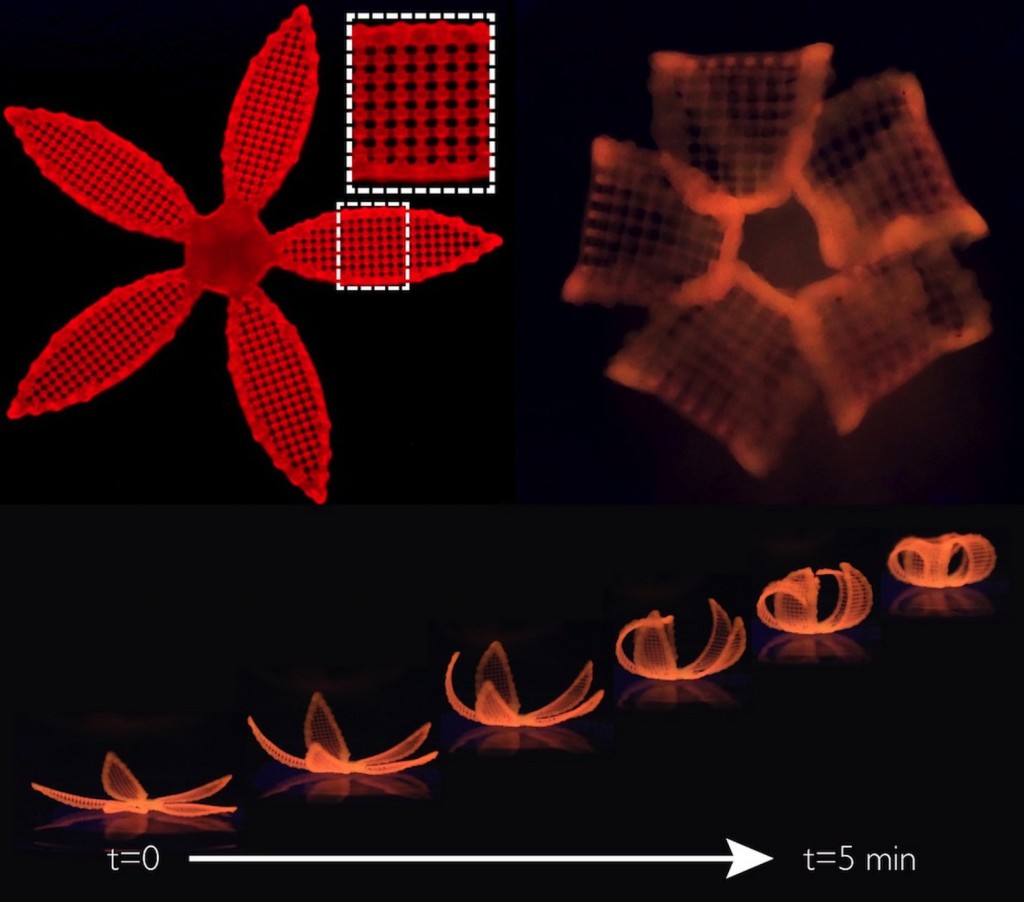

Think that 4D printing is science fiction? Take a look at some of the projects today developing the science of 4D printing and shapeshifting architecture.

When investing in those new 3D printers, be cautious of making large capital investments in a fluid and highly evolving industry. Material science and new methods will continue to change the way we practice and get me excited to think of what the future holds.

Sean

Could not agree more. I presented info on 4-D printing last year at AAO and this past year at HSO technology conference. Mind bending stuff for sure.

Dave