Resolution and 3D printing

When someone asks the question, what is the resolution of a 3D printer? There’s not a one-number answer. Resolution is a factor of polymerization kinetics, the properties of the photopolymer, and optics of the light source, and your print quality is in turn impacted by the resolution in all three dimensions: the two planar 2D dimensions (X and Y) across the build platform, and the Z dimension (the height). To even begin to have a conversation about 3D printer resolution, you will have to consider at least two numbers: the minimum feature size of the XY plane and the Z-axis resolution (layer height).

Furthermore, the planar (X and Y) and Z dimensions are generally controlled via very different mechanisms, so their resolutions will also be different and they need to be considered separately. There is also no standard that all 3D Printer manufacturers adhere to when discussing their resolution, so you begin to see why there is quite a bite of confusion about what the term “resolution” means in 3D printing.

3D Print Resolution & Minimum Feature Size

The Z-axis resolution, or layer height, for all 3D printers is easily determined and therefore widely reported even though it is less related to the overall output quality, but it is far less important to dimensional accuracy than the XY resolution and minimum feature size.

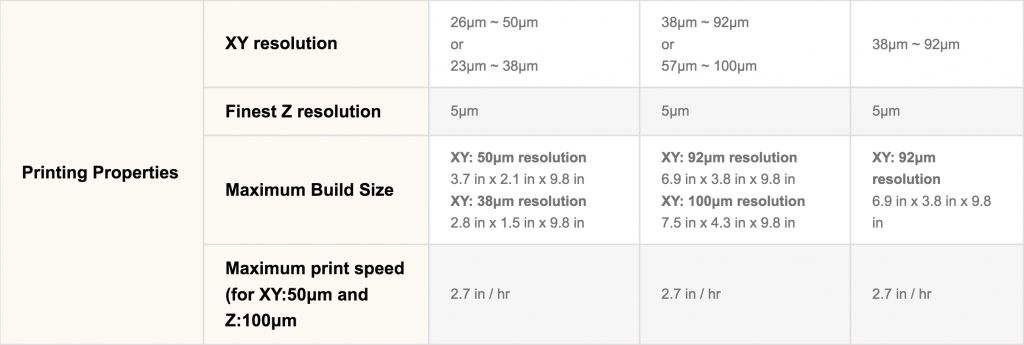

The XY resolution with DLP-SLA printers will typically be reported as a range and will tell you how small the pixels can be made by focusing the projector. As you’ll remember from our previous post, the DLP projector has a set pixel resolution so the pixels will be larger when focused on a larger surface area. Sometimes manufacturers will only give you the finest resolution and you’ll have to ask for the full range. An accurate spec sheet for printer properties for a DLP printer will look like the below image:

MSLA or LCD-masked SLA printers are a bit different since the XY resolution is determined by how the LCD photomask was manufactured and the size of the pixels on the LCD so you will in fact get a single number and not a range.

MSLA or LCD-masked SLA printers are a bit different since the XY resolution is determined by how the LCD photomask was manufactured and the size of the pixels on the LCD so you will in fact get a single number and not a range.

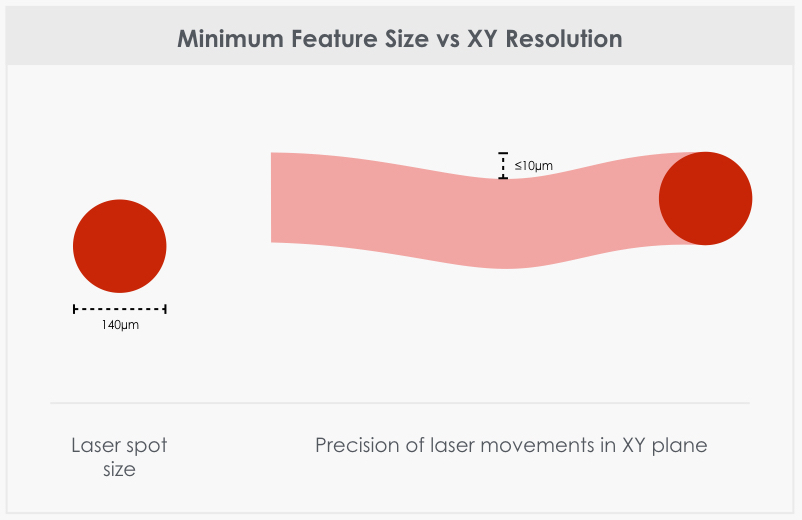

In both DLP-SLA and MSLA printers, the relationship between ‘minimum feature size’ and resolution is relatively uncomplicated. Since the layer images are projected, the XY resolution and the minimum feature size are equivalent. However, with laser SLA printers, ‘minimum feature size’ and XY resolution are related, but they are not exactly the same.

Since layers are drawn with laser SLA technology, the XY resolution determined by the pointing precision of the galvos motors (the mirrors that point the laser), and how finely they can move the laser in each layer (finer than 10microns for Form2 printer). While the ‘minimum feature size’ in a laser SLA 3D printer is equivalent to the laser spot size.

This makes comparing the XY resolution of laser SLA printers to DLP and LCD-masked printers challenging, especially considering many manufactures don’t publicize the pointing precision of proprietary galvos. Unlike DLP and MSLA, which have a fixed matrix of pixels relative to the build area, laser-based SLA machines are able to focus the laser beam on any XY coordinate. This means that laser SLA 3D printers using high-quality optics can more accurately reproduce the surface of a part even when the laser spot size is larger than the DLP pixel size.

This makes comparing the XY resolution of laser SLA printers to DLP and LCD-masked printers challenging, especially considering many manufactures don’t publicize the pointing precision of proprietary galvos. Unlike DLP and MSLA, which have a fixed matrix of pixels relative to the build area, laser-based SLA machines are able to focus the laser beam on any XY coordinate. This means that laser SLA 3D printers using high-quality optics can more accurately reproduce the surface of a part even when the laser spot size is larger than the DLP pixel size.

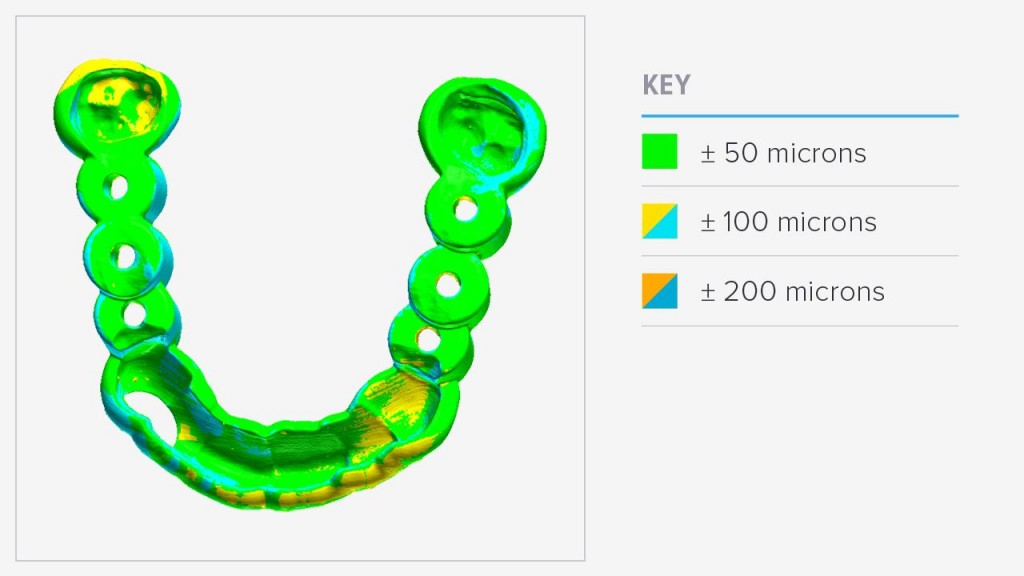

To illustrate this point about laser SLA, we can examine a dimensional accuracy study for the FormLabs Form2 printer. They examined 84 surgical guides printed with Dental SG resin and compared the printed guides with the original .STLs of the intended models and found dimensional accuracy within ± 100 microns over 93% of the surface area.For orthodontic applications, 100microns is excellent dimensional accuracy. The difference map below shows an example 3D scan of a printed surgical guide using their Dental SG resin overlaid with the original 3D model. Even though the laser spot size of the Form2 is 140microns, you can see the high dimensional accuracy produced in much finer detail than the laser spot size.

Make sure you are comparing apples to apples when examining the resolution of 3D printers for your orthodontic practice. Hopefully, this information should help.

Make sure you are comparing apples to apples when examining the resolution of 3D printers for your orthodontic practice. Hopefully, this information should help.

Leave a Reply