What is SLS?

What is SLS?

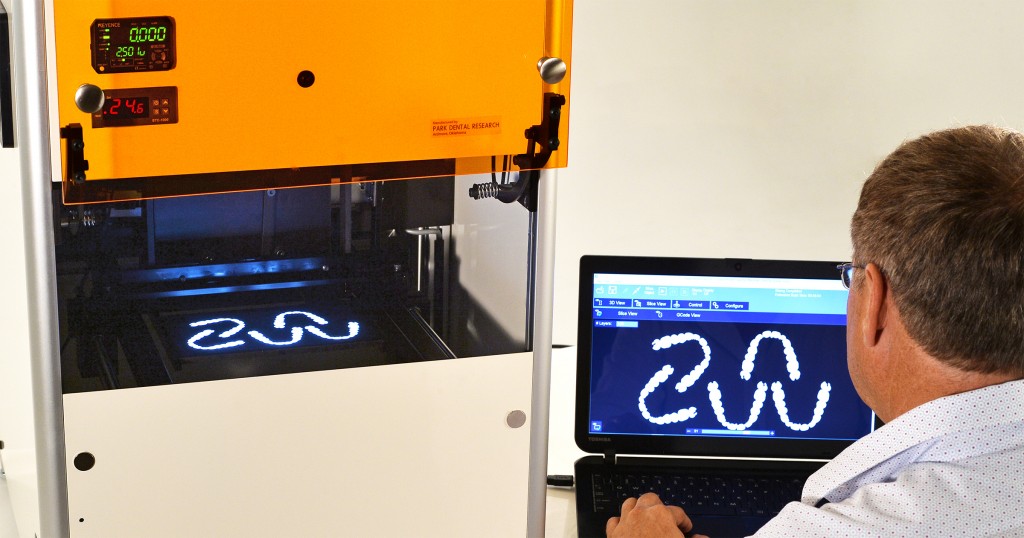

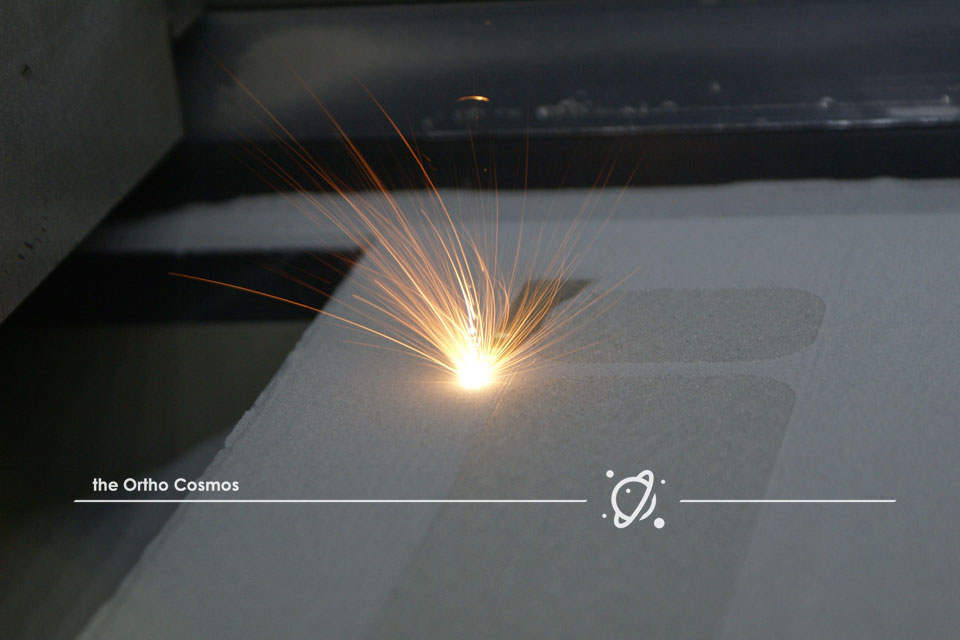

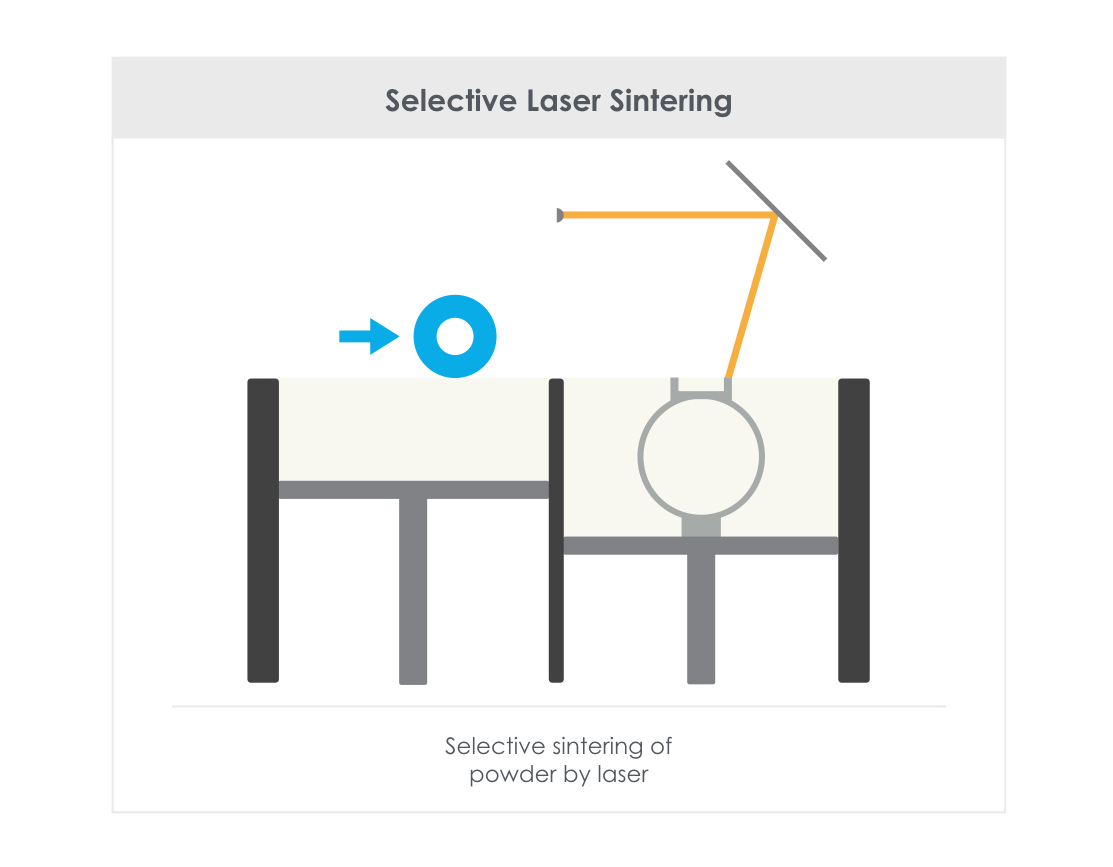

SLS stands for Selective Laser Sintering. This 3D printing technology uses a laser to harden and bond (sinter) small grains of plastic, ceramic, glass, metal, or other materials to build a 3D dimensional structure inside a hot chamber with the temperature just under the material’s sintering point. During the SLS process, the laser traces the pattern of each cross section of the 3D design onto a bed of powder. After one layer is built, the bed lowers, a roller transfers new powder to the sintering bed as needed, and another layer is built on top of the existing layers. This process is repeated until the object is complete, at which point it must be uncovered from within the un-sintered powder, and cleaned before it is ready for use. The SLS process is visualized in the diagram below:

SLS printers can use a wide range of materials including metals, always in powder form, but most often they are polyamides (Typically PA12, like Nylon) that can have additives including materials like glass and aluminum to change properties such as color, strength, flexibility, stiffness etc.

SLS printers can use a wide range of materials including metals, always in powder form, but most often they are polyamides (Typically PA12, like Nylon) that can have additives including materials like glass and aluminum to change properties such as color, strength, flexibility, stiffness etc.

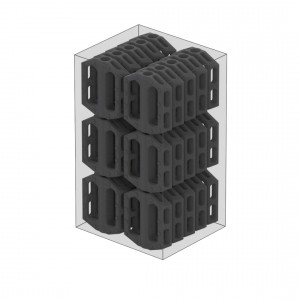

Since the product lies in a bed of powder, one of the major benefits of SLS is that it doesn’t require the support structures that many other additive manufacturing technologies use to prevent the design from collapsing during production. With no need for support structures, this technology is suitable for interlocking parts, moving parts, living hinges and other highly complex designs. You can also utilize the build volume more effectively than with SLA.

Since the product lies in a bed of powder, one of the major benefits of SLS is that it doesn’t require the support structures that many other additive manufacturing technologies use to prevent the design from collapsing during production. With no need for support structures, this technology is suitable for interlocking parts, moving parts, living hinges and other highly complex designs. You can also utilize the build volume more effectively than with SLA.

Although the use of powder provides a few advantages by serving as a support medium, the powder also raises some safety concerns. Breathing apparatuses and ventilation need to be considered, depending on the type of material.

In the future, SLS technology will likely have some applications in orthodontics because of the unique material options and the fact that it is capable of producing intricate and highly durable parts. However, the post-processing time required to uncover the prints is significant so there is less benefit to producing objects where SLS will not save your significant assembly time.