When comparing 3D printers, the first you’ll want to do is get the spec sheet for the printer and review a sample orthodontic model. Be sure and find out the resolution at which they printed the sample and which resin they used.

The spec sheet should have almost all the information you need listed on it, but you may need to ask some additional questions for clarification. I have grouped by printer what information you’ll need to gather. The rest of the stuff that the sales reps will throw at you is just fluff.

Initial Questions You’ll Need Answered

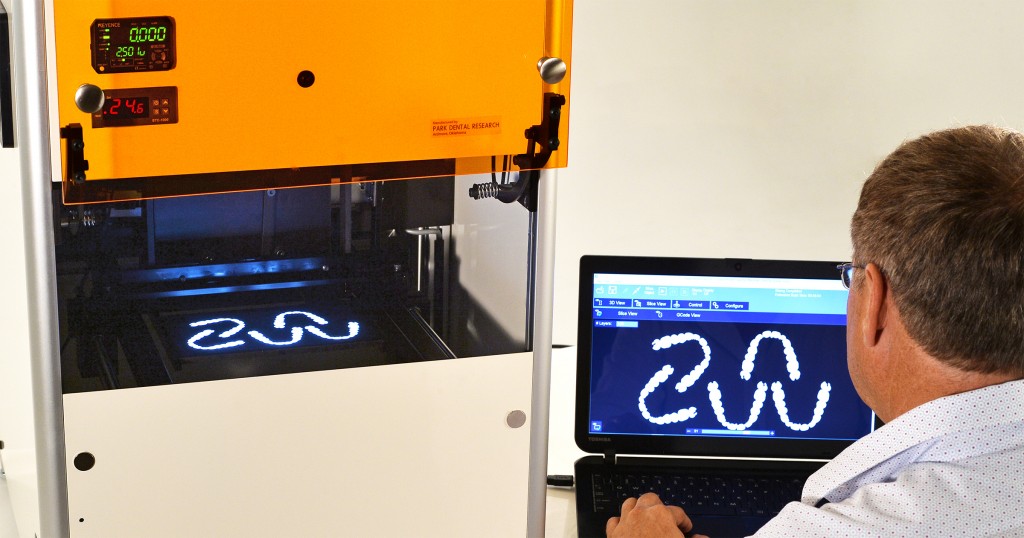

- If a software company is selling a printer bundled with their orthodontic software, ask them who actually manufactures their printer. Unless they are manufacturing the printer top to bottom themselves (highly unlikely), they are simply marking up someone else’s printer. If the sales person tries to spin you that their version is special, odds are they are lying to you (you’ll have to verify with the original manufacturer to check). This is the case with Orchestrate3D; you don’t need their software to print, and they are bullshitting doctors by claiming their printer and resin is special. You can buy the exact same printer and resins direct from Park Dental Research for a lot less.

- What light source does the printer use? They will tell you whether it is a DLP (and whether they use a commercial DLP projector or a UV-DLP projector), a Laser, or an array of LEDs masked by LCD

- Is this a Bottom-Up or Top-Down Printer? You can tell just by looking and it is almost certain that the printer will be a Bottom-Up-and-Peel style printer, but there are a few Top-Down printers in the orthodontic space. Currently CLIP is only available to rent through Carbon3D and are cost prohibitive.

- What is your build speed in mm/hr @ 100micron resolution? Again, evaluating build speed in terms of models per hour is too variable to allow for direct comparison. You’ll want to standardize this information.

- How big is the build platform? It is important to compare the size of the build platforms. Some like the Envisiontec Vida have a tiny build platforms barely the size of a 3×5 card.

- What different resins do you offer? You do not need biocompatible resins to print models, but if you want to direct print occlusal splints, denture bases, or indirect bonding trays some companies (FormLabs, Envisiontec, etc.) offer biocompatible resin materials for those purposes.

- What is the cost per liter for resin? Some companies they will obscure the cost of the resin by stating cost per model. Dental arches come in all shapes and sizes so it is hard to directly compare ongoing resin costs without standardizing the information. You’ll typically be able to print 40-60 models per liter of resin.

- What is the process to switch between resins? Depending on the design of the printer and the printing vat, it may be challenging to change between different types of resins with certain printers. This could be make or break, if you intend to switch between different types of resins frequently rather than printing models in batches.

- What training, installation, and support do you offer? Is this included? Some of the industrial printers have less than user friendly software and hardware so for some 3D printers it can help for them to hold your hand int he beginning. This is an area where you can get them to come down on price if you feel comfortable setting it up yourself.

Questions Specific to DLP-SLA Printers

- What is the layer thickness? This will be a range and reflects the Z axis resolution. This number affects surface quality and dimensional accuracy, but to a lesser degree than XY resolution.

- What is the pixel resolution of the DLP projector? Verify that their projector is an HD projector in full 1920 x 1080p and isn’t using fewer pixels.

- What is the range for your XY Resolution? Most companies are just publishing the low number in the range and your sales rep may not actually know the range.

Questions Specific to MSLA Printers

- What is the layer thickness? This will be a range and reflects the Z axis resolution. This number affects surface quality and dimensional accuracy, but to a lesser degree than XY resolution.

- What is the XY resolution? For MSLA printers, this will only be one number because there are a set number of pixels in the LCD panel. The only company utilizing this technology in the orthodontic space right now the Structo/4Qube (the US reseller). The pixel size for the Structo/4Qube Orthoform is 97microns; their Dentalform printer offers a higher resolution for crowns, etc.

Questions Specific to Laser-Based SLA Printers

- What is the layer thickness? This will be a range and reflects the Z axis resolution. This number affects surface quality and dimensional accuracy, but to a lesser degree than XY resolution.

- What is your the minimum feature size? This is roughly equivalent to the laser spot size, but the minimum feature size also takes into account the amount and the extent of resin curing around the peripheral of the laser spot.

- What is the pointing precision of your galvos? This number in microns will tell you how accurately they can move the laser and the XY resolution of printed surfaces.

Once you have gathered all the information and pricing for the full 3D printer package and you can make an apples to apples comparison, make sure you evaluate the value based on price per capacity per hour.

Leave a Reply