Looking into the Form 2 3D printer?

Looking into the Form 2 3D printer?

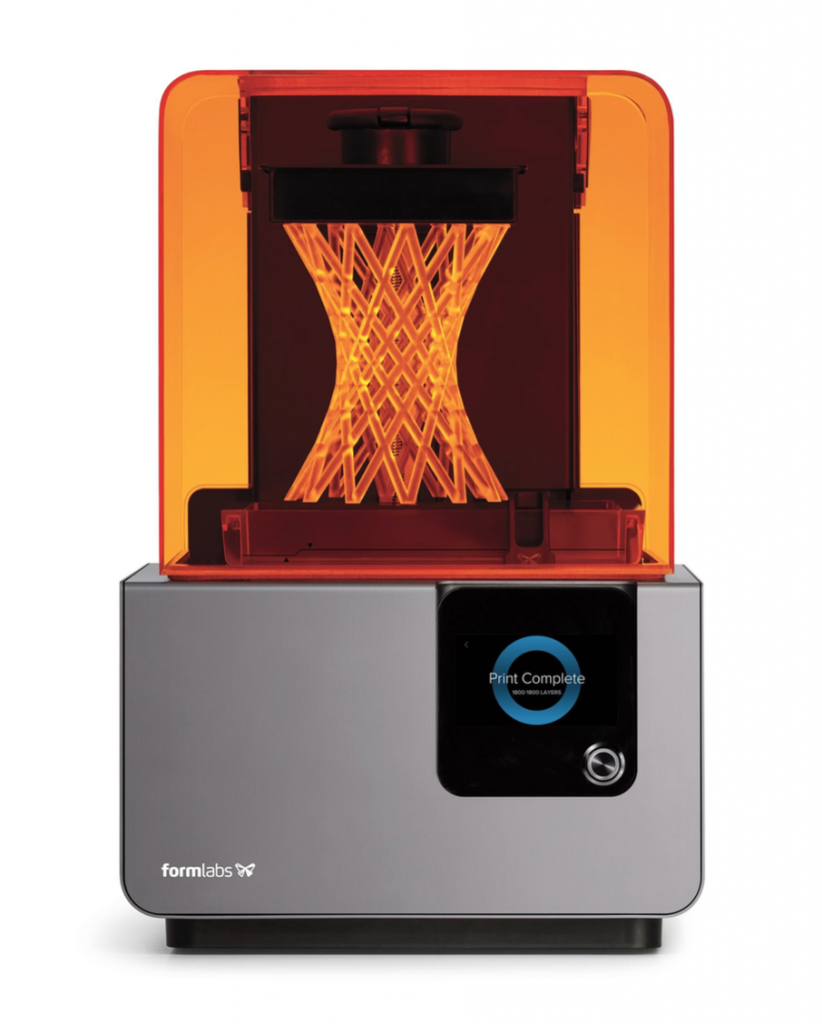

I have been 3D printing with several Formlabs printers for over 3 years and wanted to share my experience. My journey started with the original Form 1, followed by the Form 1+, and now the Form 2 is the latest version. The Form 2 printer has improved the process significantly, both in reliability and user experience. Taking into account the versatility, reliability and price point, I urge you to consider this printer if you wish to get into the 3D printing arena.

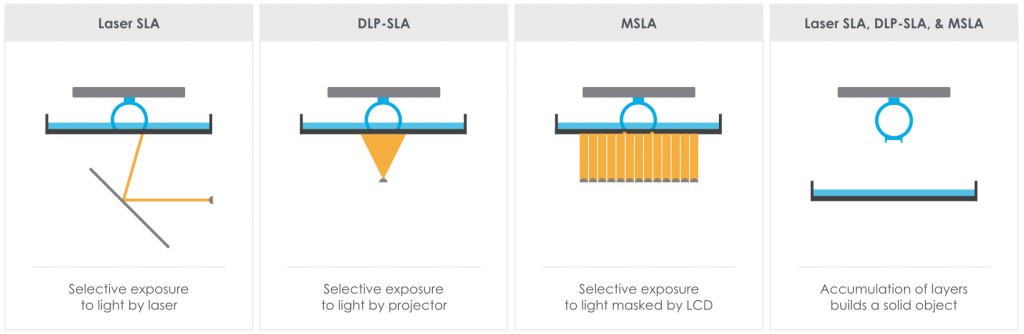

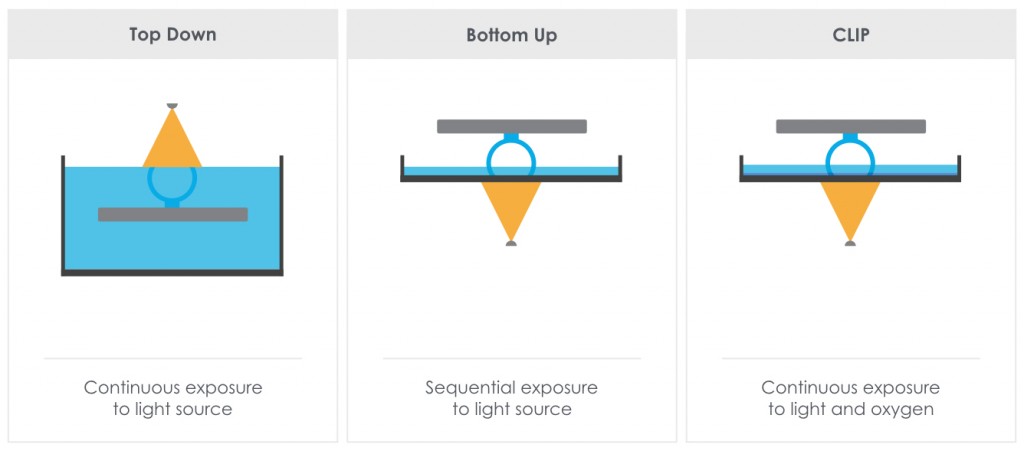

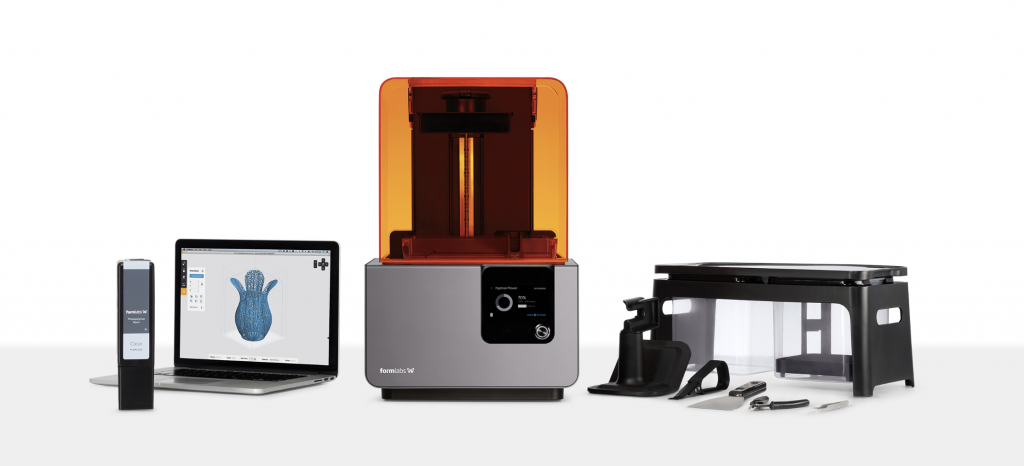

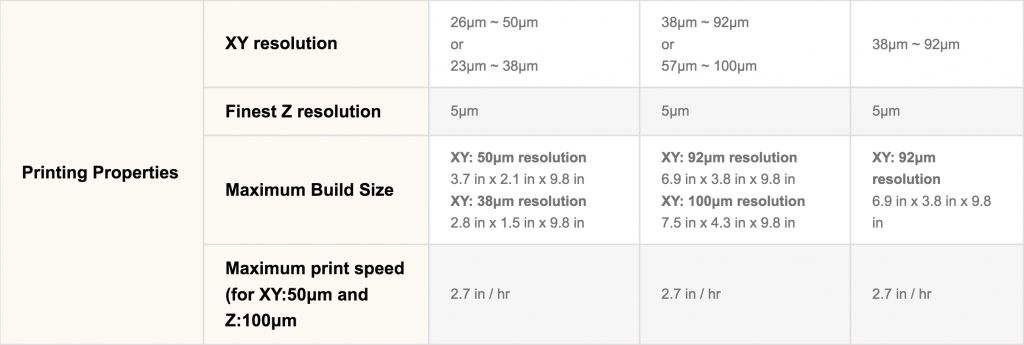

The Form 2 is a bottom up, laser based SLA printer. It uses a sliding peel process with wiper, and an automated cartridge system. Compared to its predecessors, the Form 2 has an enclosed optical path that keeps the mirrors protected from dust and contaminants. It offers Wi-Fi, Ethernet and USB connectivity, plus a touch-screen control. Its build volume is now 5.7 x 5.7 x 6.9 in.

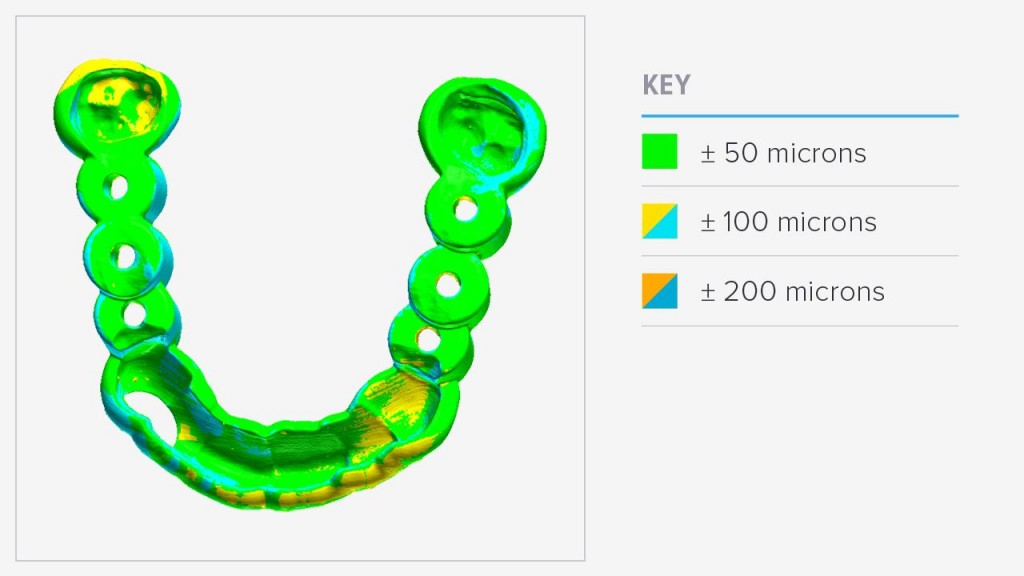

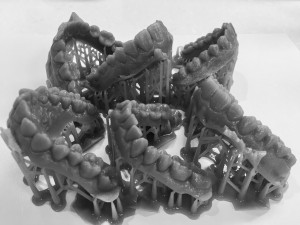

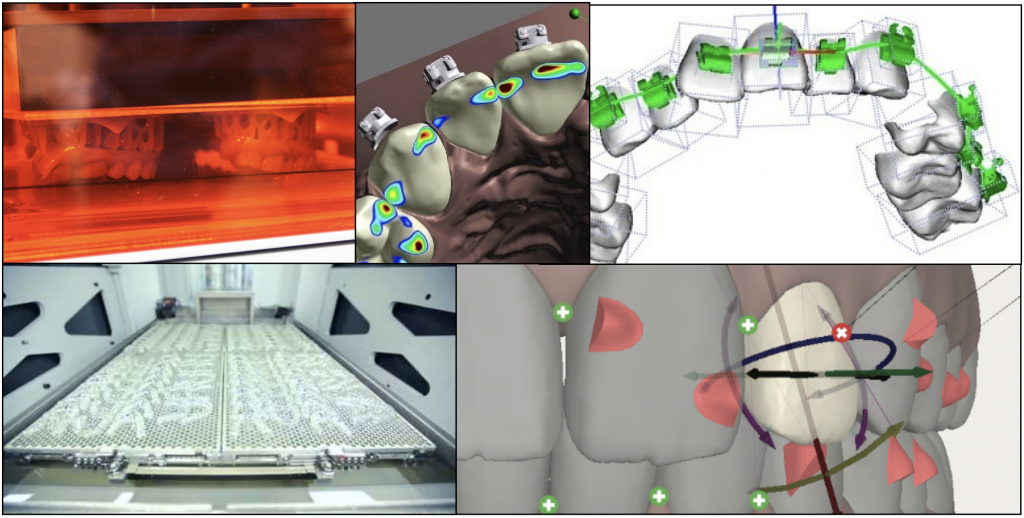

Formlabs has developed a whole line of dental and orthodontic options for 3D printing, including biocompatible resins (Dental SG & Dental LT) that can be used for direct printed splints, implant guides and IDB guides. Since 2013, I have been using their Grey resin to 3D print dental arch models for a variety of different lab fabricated appliances.

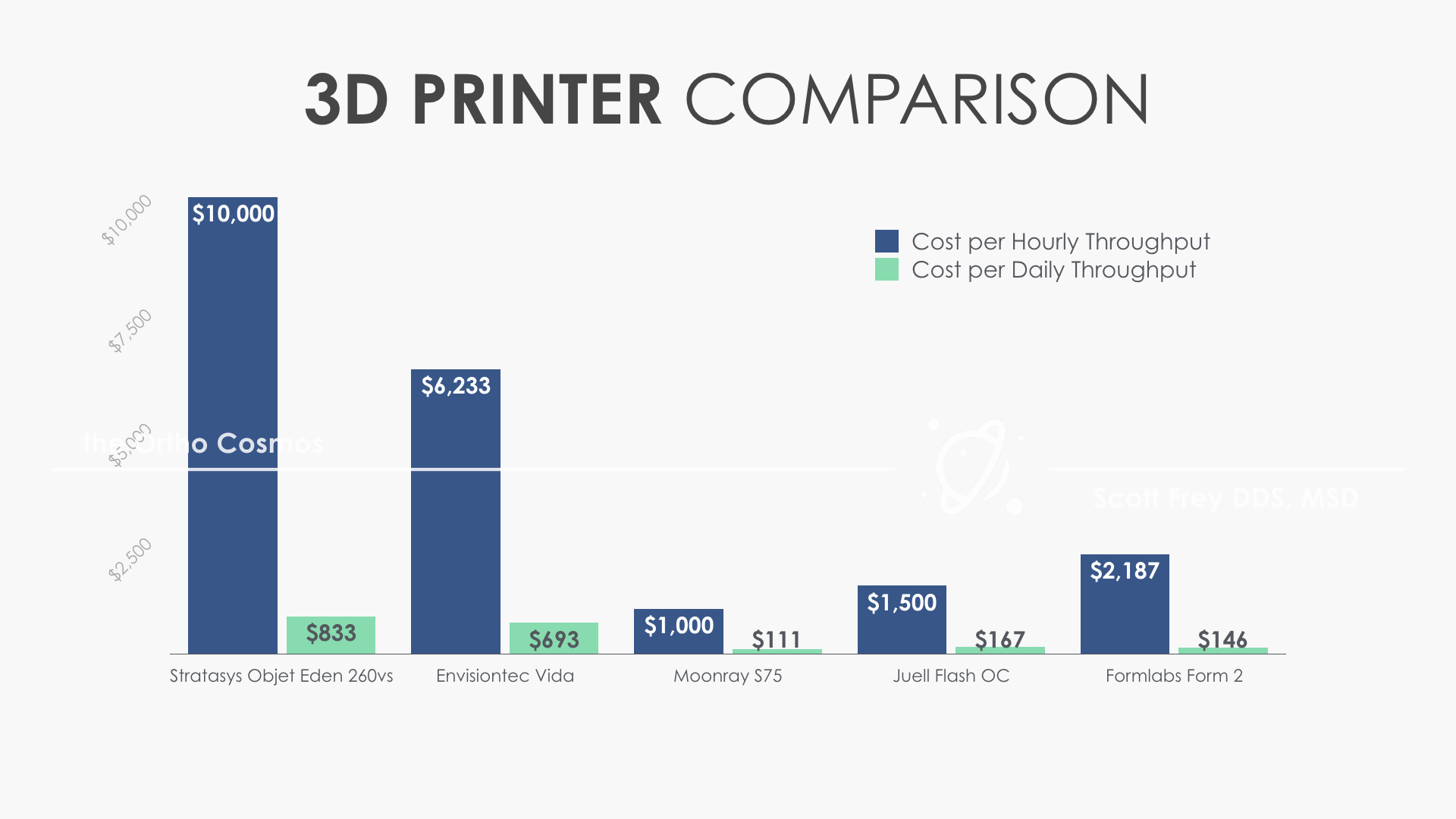

Although the Form 2 is not the fastest printer on the market, we have used it in a print farm configuration, running multiple 3D printers each day to scale our lab output. Each printer can run 8-12 dental arches per build, depending on arch size. At a price point of $3499, compared to other 3D printers in the dental market, the return on investment on this printer is excellent.

The Form 2 is available directly from Formlabs. It is essentially plug and play with intuitive software included. The Preform software and their Dashboard feature have a short learning curve and expand on the benefits of this equipment.

Stay tuned for future posts on our Form 2 setup and workflow.

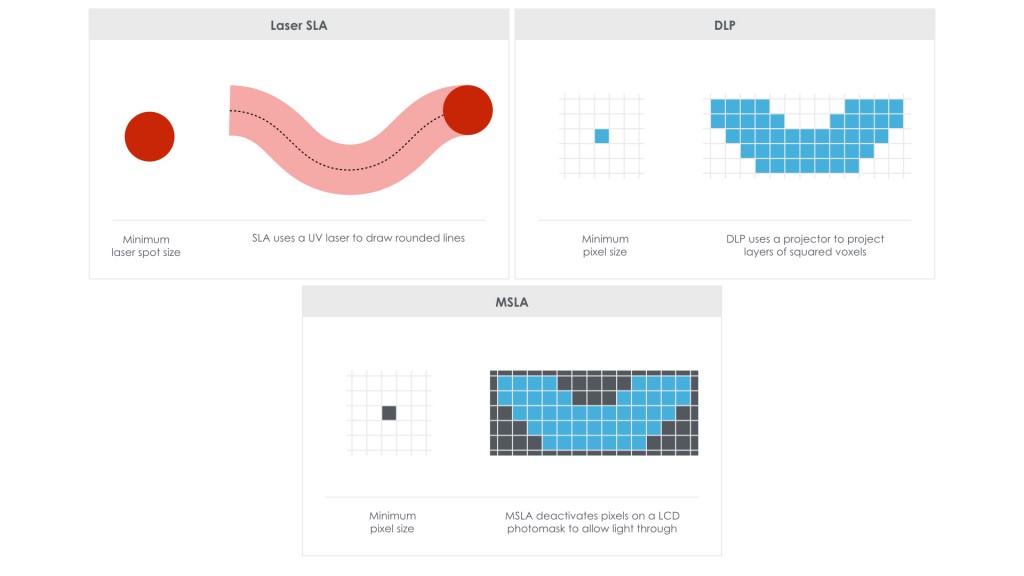

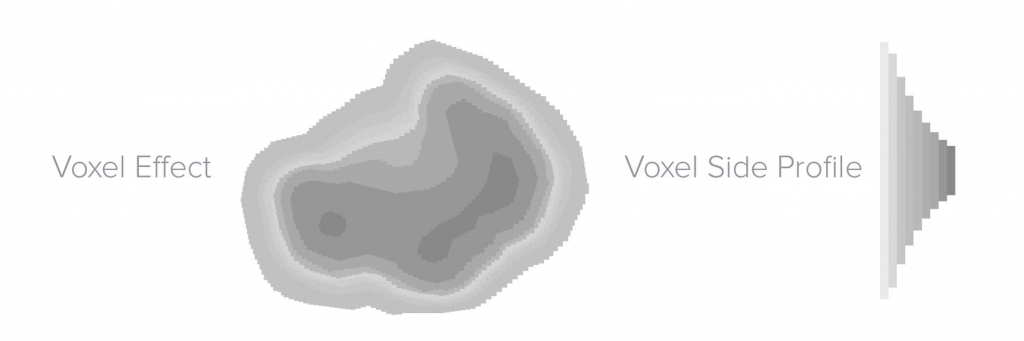

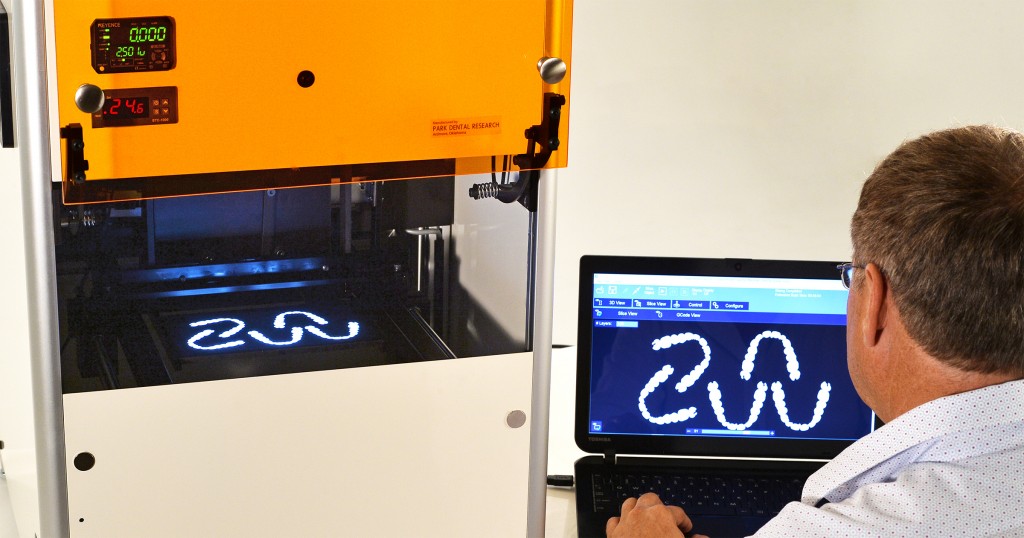

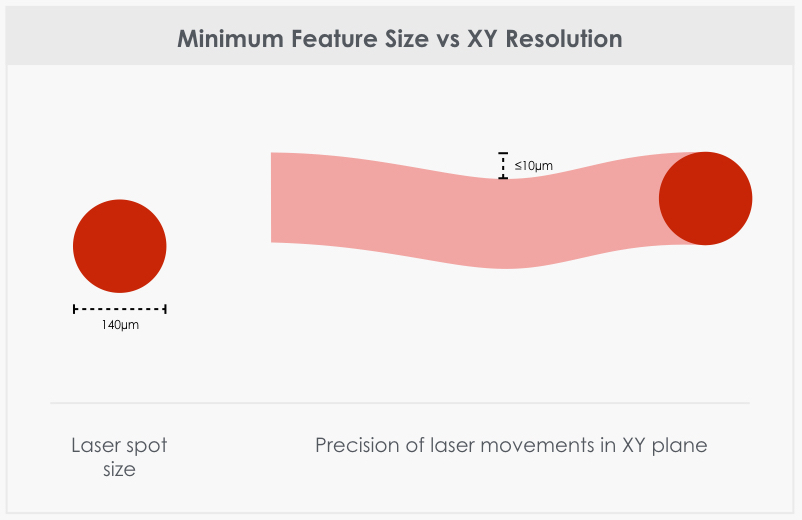

This makes comparing the XY resolution of laser SLA printers to DLP and LCD-masked printers challenging, especially considering many manufactures don’t publicize the pointing precision of proprietary galvos. Unlike DLP and MSLA, which have a fixed matrix of pixels relative to the build area, laser-based SLA machines are able to focus the laser beam on any XY coordinate. This means that laser SLA 3D printers using high-quality optics can more accurately reproduce the surface of a part even when the laser spot size is larger than the DLP pixel size.

This makes comparing the XY resolution of laser SLA printers to DLP and LCD-masked printers challenging, especially considering many manufactures don’t publicize the pointing precision of proprietary galvos. Unlike DLP and MSLA, which have a fixed matrix of pixels relative to the build area, laser-based SLA machines are able to focus the laser beam on any XY coordinate. This means that laser SLA 3D printers using high-quality optics can more accurately reproduce the surface of a part even when the laser spot size is larger than the DLP pixel size.