3D Printer Resolution

3D Printer Resolution

One of the more confusing concepts within 3D printing is understanding the resolution of the printer itself. I had several conversations during the AAO on this subject with people so I think the topic is worth revisiting.

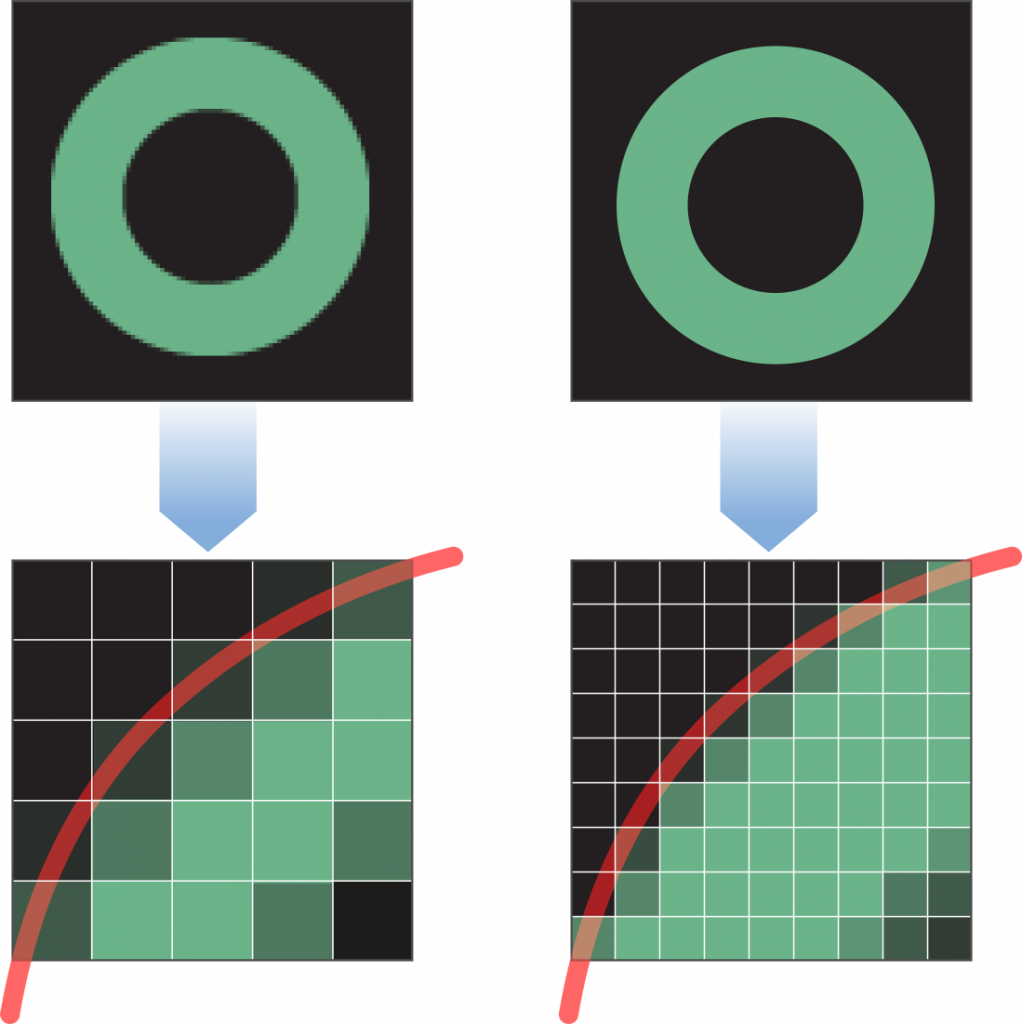

People often misquote Z axis resolutions as the printer’s “resolution” because all additive manufacturing must occur in layers, and layer thickness is something that can be roughly compared between printers. In reality the Z resolution is only a very small part of the equation. The XY resolution actually has a far more significant impact on print quality and accuracy.

Perhaps the reason why XY resolution is rarely mentioned is that you can only make a direct comparisons between XY resolutions among pixel/projector based printing technologies like DLP-SLA, MSLA, and Polyjet. You cannot really make a direct comparison between these technologies and Laser-SLA.

With DLP, MSLA, Polyjet, and other “projector” based 3D printers, their XY resolution is defined mainly by the size of the pixels. If you want to understand the XY resolution of any of these types of printers, here is how:

- DLP-SLA -> Divide the length or width of the build platform by the number of pixels in the projector for that dimension (1920 x 1080p for an HD projector), then multiple by 25,400 to convert to microns. This will give you the pixel size in microns for either the X or Y dimension (pixels are rectangular). For example , to achieve a 50micron XY resolution the build platform can only be the size of a 3×5 card with DLP printers.

- MSLA -> This technology uses an LCD photomask to shape the UV light, so the pixel size is based on how the LCD photomask is manufactured and is constant. You can simply ask the manufacturer what the pixel size is of their photomask to get the XY resolution. One advantage of this technology is that you can have high XY resolution with a larger build area.

- Polyjet -> The printers using this technology list the DPI for their projectors, which makes conversion easy. The Stratasys printer uses a 600dpi resolution in the XY, which is a 42micron XY resolution.

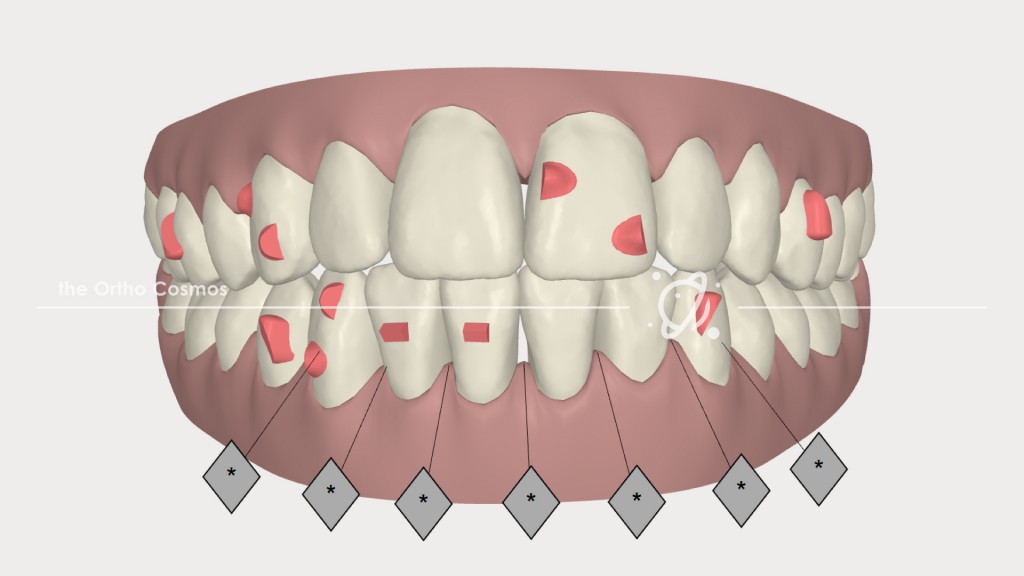

Laser-SLA printers are a completely different animal than pixel based printers (I think the featured image for this post helps highlight that difference). The XY resolution for these printers is actually determined by the pointing precision of the laser, which allows it to achieve a level of precision in the XY dimension that is finer than the laser spot size itself. For example, the pointing precision of the custom galvos on the Form2 is less than 10microns.

Now that we have clarified 3D printer resolution a little further, this should help you filter out the noise a bit better. In the end though, the resolution specifications on these machines are only a glimpse into the potential accuracy of a printer, and they don’t provide an adequate means of comparison for projector and laser-based 3D printers. The information we really want is the dimensional accuracy of the objects being produced, which we will look at from prints in a few days.

Remote 3D modeling, opens the door to a few important applications:

Remote 3D modeling, opens the door to a few important applications: